HYDRAULIC PILOT REMOTE CONTROL VALVE FOR EXCAVTOR

1. What is the Pilot Remote Control Valve?

While the Main Control Valve (MCV) handles the high-pressure, high-flow oil that moves the boom and bucket, the Pilot Valve handles low-pressure "signal" oil.

Instead of the operator physically pulling a massive lever connected to a heavy spool, they move a small joystick. This sends a precise amount of pilot pressure to the main valve, telling it exactly how much to open.

2. Key Components of the Valve Body

The valve body is a precision-machined block (usually cast iron or aluminum) that houses several internal parts:

The Housing: The main block containing internal oil galleries.

Plungers/Push Rods: These sit directly under the joystick. When you tilt the handle, you depress a plunger.

Pressure Regulating Springs: These provide the "feel" or resistance in the joystick and determine the pressure output relative to the handle's angle.

Control Spools: Small internal valves that slide to open or close the flow of pilot oil to the ports.

Damping Valves: Often included to prevent "shaking" or jerky movements when the operator releases the handle suddenly.

3. How It Works (The Process)

The operation follows a linear relationship between movement and pressure:

|

Step |

Action |

Result |

|

Neutral |

Joystick is centered. |

Pilot oil is blocked; the main valve remains closed. |

|

Initiation |

Operator moves the lever slightly. |

The plunger compresses the spring, opening the spool just a crack. |

|

Modulation |

Operator moves the lever further. |

Pilot pressure increases proportionally, pushing the main control valve spool further open. |

|

Full Stroke |

Lever hits the limit. |

Maximum pilot pressure is sent; the excavator arm moves at max speed. |

Advantage:

1.Compliant with ergonomics

2.Multi-Axis Proportional Control

3.Ergonomic Precision

4.Integrated Auxiliary Controls

5.Progressive Spring Tension

Products Display

WHY CHOOSE US

EXPERIENCED

QUALITY

R&D

We have more than 15 years of experience in this item.

Introduce well-known brand processing equipment and provide QC reports.

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

OUR CERTIFICATES

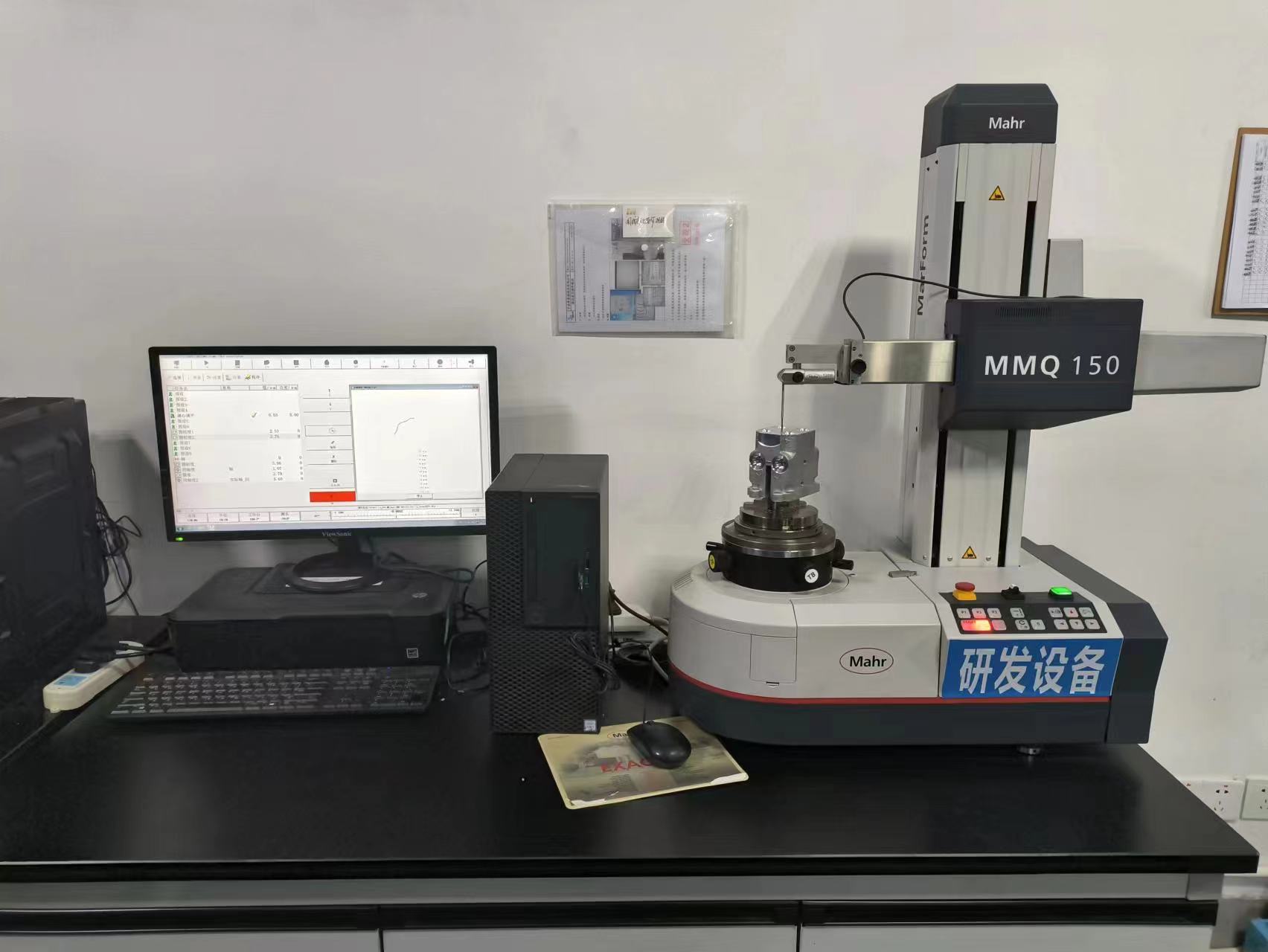

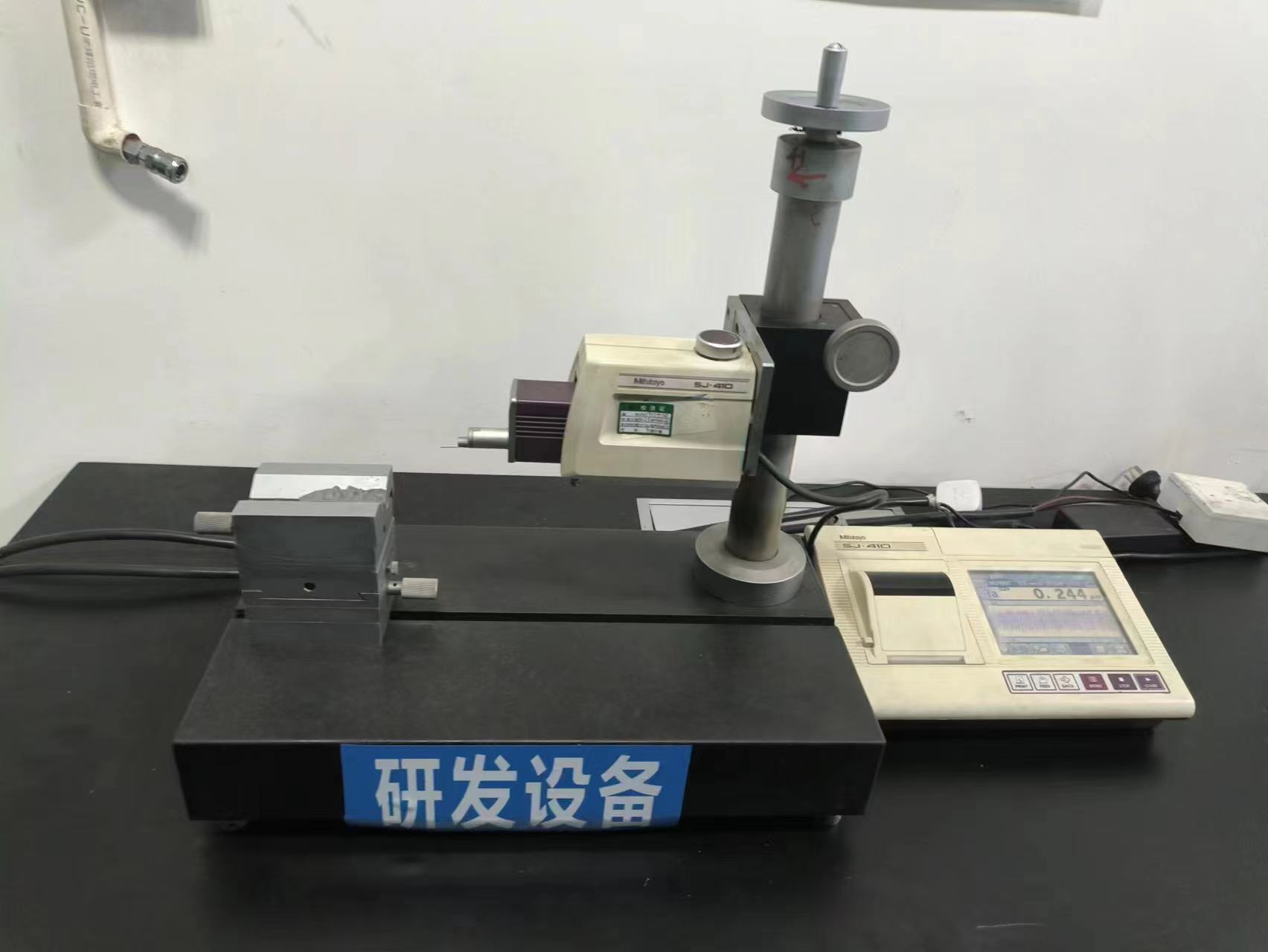

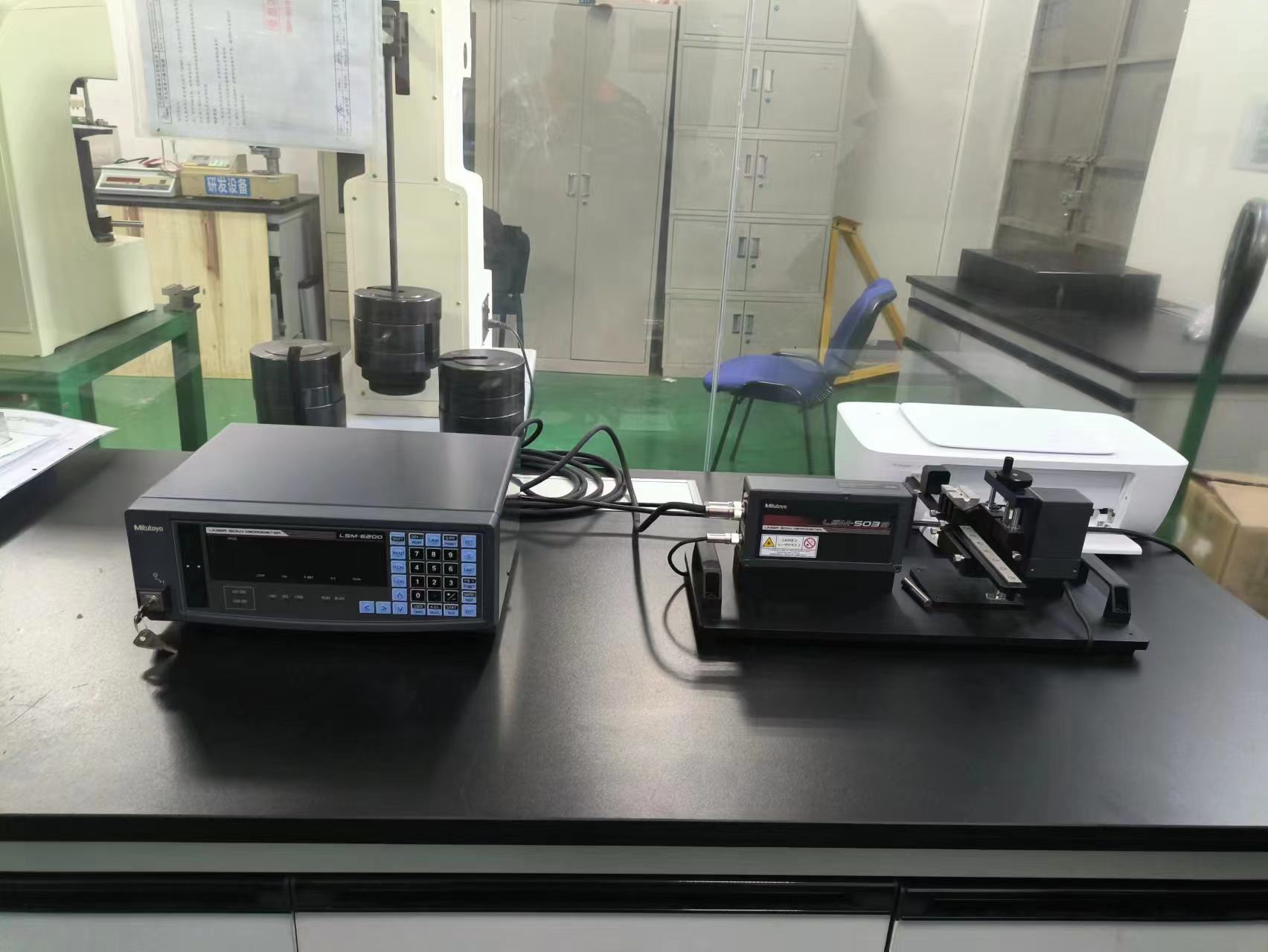

Quality Control Equipment

To ensure the quality of factory products,we introduce advanced cleaning and component testing instruments, 100% of the assembled products pass factory testing and the test data of each product is saved on a computer server.

R&D team

Our R&D team consists of 10-20 people, most of whom have about 10 years of work experience.

Our R&D center has a sound R&D process,including customer survey, competitor research, and market development management system.

We have mature R&D equipment including design calculations, host system simulation, hydraulic system simulation, on-site debugging, product testing center, and structural finite element analysis.

OUR PARTNER

Over the past decade,as a trusted supplier, Ningbo Flag Hydraulic Co., Ltd. provides supporting equipment for large and powerful domestic enterprises such as Sunward Intelligent, XCMG, Sany Heavy Industry, and Zoomlion.

-

81090152-PDF

81090152-PDF