In heavy industries such as mining, port loading and unloading, and construction machinery, hydraulic winches, with their powerful pulling force and stable operating performance, have become essential equipment for material lifting and hauling operations. However, many industry practitioners will find that hydraulic winches require a hydraulic power unit (HPU) for proper operation. What is the technical logic behind this “golden partnership”? Why does the HPU become the “heart” and “brains” of the hydraulic winch?

I. HPU: The “Power Source” of the Hydraulic Winch, Enabling Precise Energy Conversion

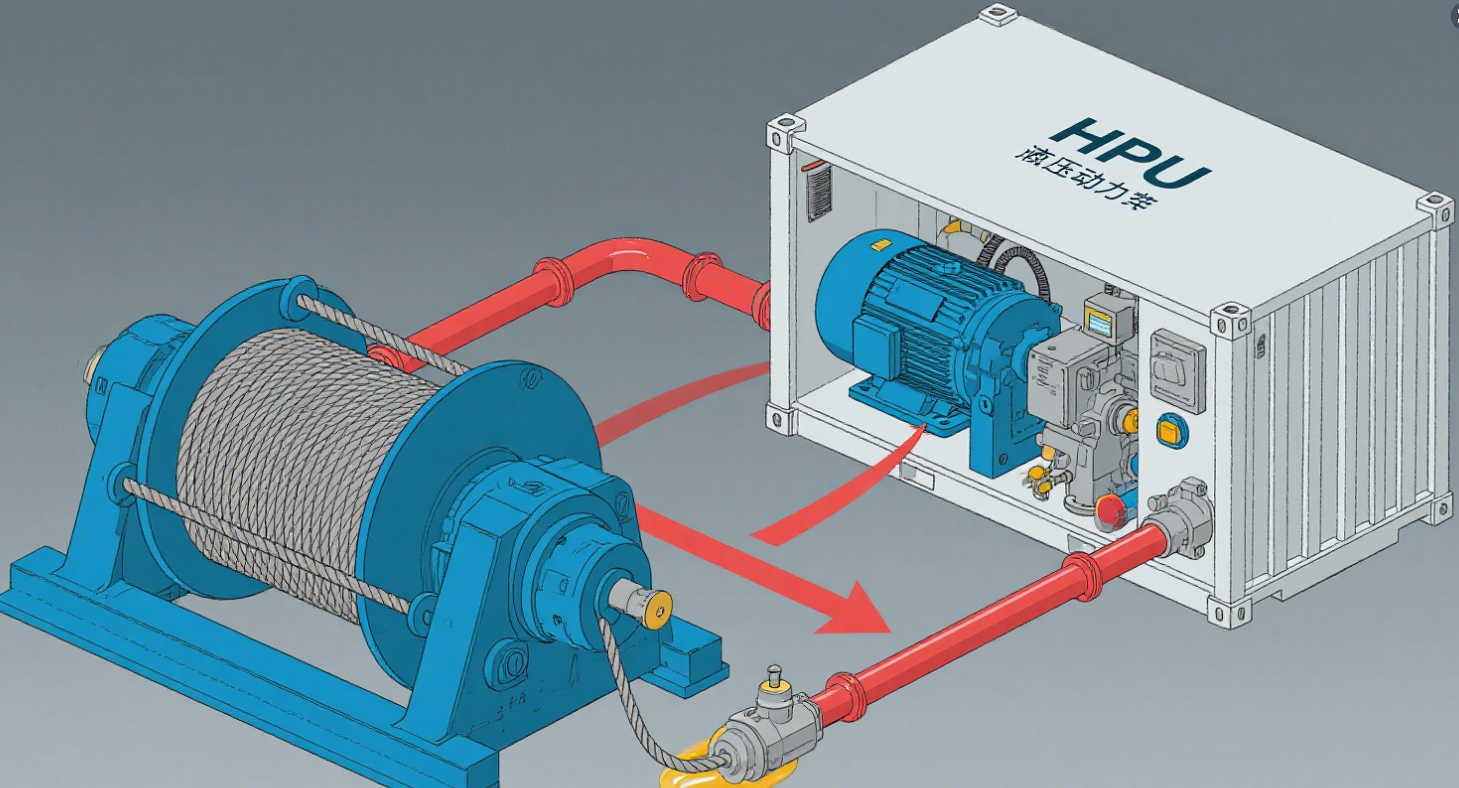

The core working component of a hydraulic winch is the hydraulic motor, which relies on high-pressure oil to operate—this critical power source is provided by the HPU. In actual operation, the HPU uses an electric motor or diesel engine to drive a hydraulic pump, efficiently converting electrical or mechanical energy into hydraulic energy. This energy is then transported as high-pressure oil through pipelines to the hydraulic winch’s hydraulic motor. “Without an HPU, a hydraulic winch is like a car without power—it simply won’t start,” explained Mr. Li, an engineer at a heavy machinery manufacturing company. “Different operating scenarios require varying traction forces. The HPU can adjust the hydraulic pump’s output pressure to match the hydraulic winch’s traction force from tens to hundreds of kilonewtons, meeting the diverse needs of mining, port, and bridge construction.”

The core working component of a hydraulic winch is the hydraulic motor, which relies on high-pressure oil to operate—this critical power source is provided by the HPU. In actual operation, the HPU uses an electric motor or diesel engine to drive a hydraulic pump, efficiently converting electrical or mechanical energy into hydraulic energy. This energy is then transported as high-pressure oil through pipelines to the hydraulic winch’s hydraulic motor. “Without an HPU, a hydraulic winch is like a car without power—it simply won’t start,” explained Mr. Li, an engineer at a heavy machinery manufacturing company. “Different operating scenarios require varying traction forces. The HPU can adjust the hydraulic pump’s output pressure to match the hydraulic winch’s traction force from tens to hundreds of kilonewtons, meeting the diverse needs of mining, port, and bridge construction.”

II. Precision Control: The “Brain”: The HPU Makes Winch Operations More Flexible and Controllable

In addition to providing power, the HPU also serves as the “control center” of the hydraulic winch. Within the HPU’s integrated system, various control valves, including pressure valves, flow valves, and directional valves, work together to precisely regulate the pressure, flow rate, and flow direction of the hydraulic oil—a key factor that directly determines the hydraulic winch’s operating speed, pulling direction, and operating accuracy. For example, during container loading and unloading operations at ports, the HPU’s flow valve allows hydraulic winches to slowly raise and lower the wire rope, preventing damage to containers caused by impact. During bridge cable pulling operations, the HPU’s pressure valve monitors system pressure in real time, ensuring the pulling force remains within a safe range and preventing cable overload and breakage. A port operations manager stated, “Thanks to the HPU’s precise control, our hydraulic winch operating efficiency has increased by 20% while reducing equipment failure rates by 15%.”

III. Ensuring System Stability: The HPU “Guards” Hydraulic Winches

The stable operation of hydraulic systems depends on clean oil and a suitable operating temperature—another core function of the HPU. A reporter observed at a construction machinery production workshop that a standard HPU typically integrates auxiliary components such as an oil tank, oil filter, and cooler. The oil tank stores sufficient oil for the system and also serves to precipitate impurities. The high-precision oil filter removes contaminants such as dust and metal debris from the oil, preventing wear on precision components such as hydraulic motors and valves. The cooler effectively reduces oil temperature, preventing excessive oil temperature from causing a decrease in hydraulic oil viscosity and unstable system pressure.

“Hydraulic components require extremely high oil cleanliness. Even micron-sized impurities can cause valve sticking and motor wear,” explained Engineer Li, pointing to the HPU’s filter assembly. “The HPU’s oil purification and temperature control functions extend the life of the hydraulic winch, reduce maintenance downtime, and lower the company’s operating costs.”

IV. Safety Protection “Barrier”: The HPU strengthens operational safety.

In high-risk operations, the safety protection functions of the HPU are even more critical. Currently, mainstream HPUs all integrate safety devices such as overload protection valves and emergency brake valves. When the hydraulic winch’s system pressure exceeds the set value due to excessive load, the overload protection valve automatically opens to release excess pressure, preventing damage to the hydraulic motor and wire rope. In emergencies such as sudden power outages or pipeline ruptures, the HPU’s emergency brake valve instantly cuts off the oil supply, bringing the hydraulic winch to a complete stop, preventing accidents like heavy objects falling or slipping.

This safety feature is particularly important in underground mining operations. A mine safety officer told reporters, “Underground working space is confined, and a hydraulic winch failure would have disastrous consequences. The HPU’s safety protection system acts as a ‘safety valve,’ repeatedly preventing safety hazards caused by equipment overload.”

V. Adaptability to Diverse Working Conditions: HPUs Make Hydraulic Winches “Ubiquitous”

The environmental conditions in different operating scenarios vary significantly, and the HPU’s flexible design enables hydraulic winches to perform effectively in a variety of complex working conditions. For factories and ports with stable power supplies, electric-powered HPUs are the preferred choice due to their low noise and zero emissions. For off-grid environments like field exploration and open-pit mines, diesel-powered HPUs can provide continuous power to hydraulic winches using their own power source.

HPUs can also be customized based on factors such as operating environment temperature, humidity, and dust concentration. For example, in cold regions, HPUs are equipped with oil heaters to prevent oil freezing at low temperatures; in humid coastal environments, HPU metal components are coated with an anti-corrosion coating to enhance corrosion resistance. This high adaptability makes hydraulic winches widely used in various scenarios, including on land, at sea, and on plateaus.

Conclusion: HPUs and hydraulic winches form the “power foundation” of industrial operations.

From power supply to precise control, from system stability to safety protection, the HPU, with its multiple core functions, has become an indispensable partner for hydraulic winches. With the advancement of industrial automation and intelligence, HPUs are also undergoing continuous upgrades. Today, intelligent HPUs integrated with IoT technology enable remote monitoring and fault warnings, further improving the efficiency and reliability of hydraulic winches.

Industry experts indicate that the future collaborative development of HPUs and hydraulic winches will place greater emphasis on energy conservation, environmental protection, and intelligence, providing stronger support for green transformation and efficient production in the heavy industry sector. Understanding the technical logic behind this “golden partnership” will also help more industry practitioners better apply the equipment and improve operational efficiency.

Post time: Aug-28-2025