In industries such as construction machinery, lifting and transportation, metallurgy, and port equipment, the precision, stability, and efficiency of control directly impact operational results and equipment lifespan. Traditional direct hydraulic control systems often rely on operators directly driving the main valve, which is labor-intensive, slow to respond, and offers limited control accuracy. So, how can we reduce operational effort while achieving smoother and more reliable motion control?

The hydraulic pilot system is a mature solution designed to address these challenges. Through its intelligent design of “low-pressure signal controlling high-pressure main circuits,” it not only significantly reduces operational effort but also greatly enhances control quality and overall system performance. The following sections will explore how this technology enables reliable and efficient operation in modern construction machinery from the perspectives of control experience, precision response, system integration, safety, and durability.

Effortless Control, Free from Fatigue

Traditional hydraulic operation relies on manual force to directly push the main valve stem, which can easily lead to operator fatigue during prolonged work. The hydraulic pilot system, however, uses a pilot handle to output low-pressure control signals, allowing high-pressure main circuits to be activated with gentle movements. This greatly reduces physical strain during operation, making continuous work easier and more ergonomic.

Precise Response, Smooth Operations

Pilot signals offer excellent linearity and fine flow regulation, enabling precise micro-movements and smooth starts and stops of equipment. This makes actions such as digging, lifting, and slewing smoother and more accurate, reducing impact, vibration, and component wear. It is particularly suitable for applications requiring high precision, enhancing both operational quality and equipment durability.

Integrated Layout, Simplified Systems

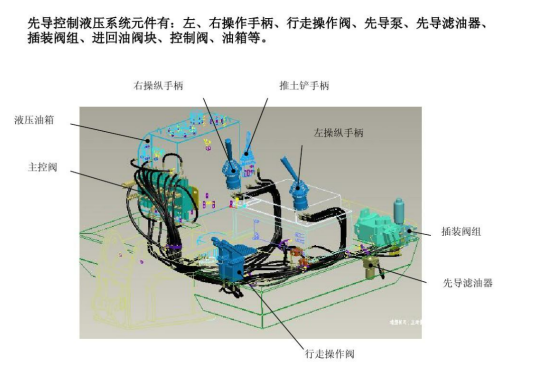

Represented by Flaiige’s integrated oil supply blocks, the system combines functions such as pressure stabilization, filtration, and overflow into a single unit. This reduces pipeline connections and leakage risks, minimizes pressure loss, and allows for more compact spatial arrangements. An independent pilot oil supply ensures stable signal output, supporting coordinated work among multiple actuators to meet complex operational demands.

Safety, Reliability, and Long-Term Stability

The isolation between the low-pressure pilot circuit and the high-pressure main circuit enhances system safety. Coupled with overload protection and pressure stabilization mechanisms, the failure rate is significantly reduced. Additionally, high-quality materials and precision engineering ensure that pilot components are resistant to vibration, contamination, and temperature variations, guaranteeing long-term stable performance even in harsh environments and reducing maintenance costs.

With pilot handles and oil supply blocks at its core, Ningbo Flag-up Hydraulics continues to provide highly reliable, easily integrated, and precise pilot control solutions. This helps equipment manufacturers enhance the control ability and operational efficiency of their products, making it an ideal choice for upgrading many types of construction machinery.

From the analysis above, it is clear that the hydraulic pilot system not only resolves the traditional trade-off between effort and precision in control but also enhances overall reliability through systematic design—this is the fundamental reason why it empowers modern construction machinery to operate efficiently, precisely, and stably.

Post time: Feb-07-2026