In engineering machinery, construction machinery, mining machinery, and other fields, slewing drives are core components that enable equipment rotation, and their performance directly impacts the overall machine’s operating efficiency and stability. The FHZ series slewing drive, developed by Ningbo Flag-up Transmission Co., Ltd., has become a preferred choice for drive systems in various industries due to its unique design and reliable performance. The reasons behind this are worth exploring.

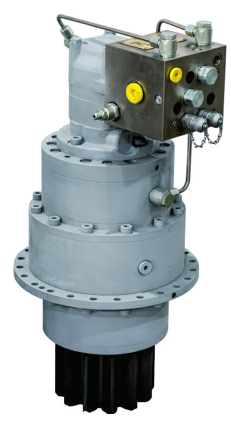

Structurally, the FHZ series slewing drive consists of a built-in multi-disc wet parking brake and a cantilevered planetary reducer. Utilizing advanced modular manufacturing concepts and sophisticated processing techniques, it boasts a compact structure while ensuring load capacity and operational reliability. This design enables efficient power transmission within limited space, adapting to the needs of equipment of varying sizes. Its wide range of applications is one of its core advantages. This series of products has been widely used in drive systems for engineering machinery, construction machinery, mining machinery, and other applications, such as marine crane slewing, large cranes, pipelayers, and crawler pile frames, performing reliably. A diverse selection of models further broadens the application scope. Its maximum output torque ranges from 5000 N·m to 93300 N·m, and its flexible gear ratio range allows it to be paired with various hydraulic motors or electric motors, meeting the diverse needs of equipment from small and medium-sized to large-scale engineering. Its stringent standards and reliable performance have established its market trust. The maximum output torque of the FHZ series slewing drive unit is based on the FEM standard, 3rd edition, Chapter 1, and operating levels meet specifications such as M5, 75, and 12, ensuring stability under high-intensity operation.

In addition, the company’s CCS product certification and ISO9001:2015 quality system certification ensure comprehensive quality control from design to production, ensuring efficient operation even under complex operating conditions.

Furthermore, its flexible customization capabilities are key to its success. This series of slewing drives can be adapted to accommodate other motor/electrical models and various functional valve blocks based on actual operating conditions. Specific external and connection dimensions can also be adjusted directly upon consultation. This user-centric design approach significantly enhances the product’s adaptability and practicality. It is precisely due to the advanced structural design, wide range of application scenarios, reliable performance and customization flexibility that the FHZ series slewing drive has become a core component of drive systems in multiple industries, providing solid support for the efficient operation of the equipment industry.

Post time: Jul-30-2025