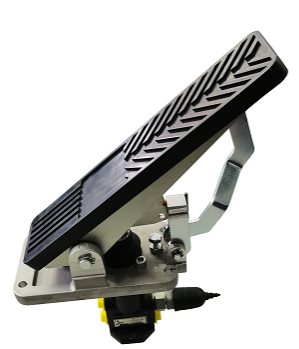

This brake valve has outstanding performance in terms of functions, applicable fields and product features, bringing a new braking solution to the field of engineering equipment. The differentiated design of single-circuit and dual-circuit brake valves meets the needs of different scenarios.

In terms of product functions, this positive regulation brake valve is designed for quantitative systems, closed systems or load-sensitive systems. When used in conjunction with the accumulator charging valve and the adapter accumulator, it can not only achieve conventional braking, but also reliably play a braking role in the emergency situation of power failure, providing double protection for the safe operation of the equipment. Its pressure response is fast and the adjustment is smooth. The pedal force is proportional to the brake pressure output, allowing the operator to accurately control the braking process, greatly improving the stability and controllability of the brake.

Single-circuit and dual-circuit brake valves are in the same core function, but they have different focuses on system safety design.

The single-circuit brake valve uses a single hydraulic circuit to control the braking system, with a relatively simple structure and low cost. It is suitable for scenes with relatively basic requirements for braking safety, light equipment load or simple working environment, such as small agricultural machinery, light engineering machinery, etc. It transmits brake pressure through a single path, with direct operation response and convenient maintenance.

The dual-circuit brake valve adopts an independent dual hydraulic circuit design, and the two circuits work independently of each other. When one of the circuits fails, the other circuit can still maintain some braking function, which greatly reduces the risk of brake failure caused by failure of a single circuit and is safer. Therefore, dual-circuit brake valves are widely used in large-scale engineering equipment, heavy trucks, port machinery, etc. with extremely high requirements for braking safety, especially for equipment operating under heavy load, high speed or complex working conditions.

From the perspective of the applicable fields and scope, this brake valve has a wide range of applications. The specific information is as follows:

| Item | Specific Content |

| Working Medium | Mineral-based hydraulic oil |

| Viscosity Range | 2.8 – 380mm²/s |

| Hydraulic Oil Temperature Range | -30℃ to 107℃ |

| Applicable Scenarios | Frequent braking of heavy – duty equipment in mining operations, flexible starting and stopping of various construction machinery at construction sites, precise braking of vehicles in port logistics, etc. |

| Maximum Input Pressure of the Whole Series | 210bar |

| Brake Pressure Setting Range | 20 – 200bar |

| Standard brake valve pressure set point intervals | 5bar |

From the perspective of product features, the brake valve has significant advantages. The specific information is as follows:

| Product Features | Details |

| Structural Design | Compact structure, suitable for installation in narrow spaces, enhancing the installation flexibility of engineering equipment with limited space |

| Cleanliness Requirement | Grade 18/16/13 (ISO4406) |

| Maximum Return Oil Pressure | Not exceeding 1bar, ensuring long – term stable operation in complex hydraulic environments |

This new brake valve of Ningbo Flag-up Hydraulics Co., Ltd. will undoubtedly become a leader in the field of engineering equipment braking with its excellent functions, wide range of applications and outstanding product features, especially the differentiated design of single circuit and dual circuit, and will inject new impetus into the development of the industry.

Post time: Jul-09-2025