Proper power sourcing for a hitch mounted winch is crucial. It ensures efficient operation and prevents potential accidents. Safety considerations are paramount. Operators should avoid standing in the danger zone, adhere to the winch’s rated workload, and remain aware of their surroundings. These precautions help mitigate risks associated with winching operations.

Key Takeaways

- Choose the right power source for your hitch winch. Options include batteries, jump start boxes, and direct vehicle power. Each has its pros and cons.

- Always prioritize safety. Avoid standing in the danger zone, adhere to the winch’s rated workload, and inspect equipment before use.

- Regularly check and maintain your winch. Inspect cables for fraying and ensure all connections are secure to prevent accidents.

Power Sources for Hitch Mounted Winch

Batteries

Batteries serve as a common power source for hitch mounted winches. They provide a reliable and portable option for users who need to operate their winches away from their vehicles. However, there are advantages and disadvantages to consider when using batteries.

- Advantages:

- Batteries allow for flexibility in winch placement, enabling users to work in various locations without relying on vehicle power.

- They are particularly effective for work trucks and off-road vehicles that are used occasionally.

- Disadvantages:

- A winch powered by the vehicle’s primary battery can lead to the battery being drained, preventing the vehicle from starting.

- Electric winches typically have limited pull capacity compared to hydraulic winches, which may affect performance in demanding situations.

For optimal performance, a 100 ah Group 27 deep cycle battery is recommended. This battery can maintain 12 volts or higher with a 40 amp load for about 55-60 minutes of runtime down to 40% depth of discharge (DOD). Under an 80 amp load, it provides around 45 minutes of runtime down to 11 volts at 80% DOD. This battery is rated to perform this cycle 500 times, making it a durable choice for frequent use.

Jump Start Boxes

Jump start boxes offer another practical solution for powering a hitch mounted winch. These portable power sources are designed to provide a quick boost to a vehicle’s battery, but they can also supply power to winches.

- Benefits:

- Jump start boxes are compact and easy to transport, making them ideal for off-road adventures.

- They eliminate the risk of draining the vehicle’s battery, ensuring that the vehicle remains operational.

However, users should ensure that the jump start box has sufficient capacity to handle the winch’s power requirements. Not all jump start boxes are created equal, so checking the specifications is essential.

Direct Vehicle Power

Connecting a hitch mounted winch directly to vehicle power is another viable option. This method can provide a steady power supply, but it comes with certain risks.

To connect a winch directly to the vehicle’s power, follow these steps:

- Use a set of booster cables, cut one end, and install a plug on one end to connect to the winch.

- Run heavy gauge copper cable from the truck’s battery to the winch, as the power near the hitch may not provide sufficient amps.

While this method can be effective, it poses risks. Electric winches can create excessive line tension, potentially damaging the vehicle or the winch itself. Lack of feedback during operation can lead to over-tensioning, risking equipment failure. Additionally, winch cables can cause serious injuries if they snap or recoil unexpectedly. Proper attachment of the load to the cable is crucial to prevent detachment and potential injury.

Wiring Instructions for Hitch Mounted Winch

Wiring a hitch mounted winch requires careful attention to detail. Proper wiring ensures that the winch operates efficiently and safely. Below are the essential tools needed for the wiring process, followed by step-by-step connection instructions.

Required Tools

Before starting the wiring process, gather the following tools:

- Wire Strippers: These help in stripping the insulation from the wire ends.

- Crimping Tool: This tool secures connectors to the wire.

- Wrenches or Socket Set: Use these for tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for securing connections.

- Heat Shrink Tubing: This provides insulation and protection for exposed wire connections.

- Electrical Tape: Use this to secure and insulate connections.

- Multimeter: This tool checks voltage and continuity in the wiring.

Connection Steps

Follow these steps to wire your hitch mounted winch correctly:

- Prepare the Wiring: Cut the wires to the appropriate lengths. Ensure wire ends are cut and stripped according to the winch wiring kit guidelines.

- Connect to Power Source: Choose a reliable power source, such as a battery or jump start box. Secure connections to the battery using appropriate connectors.

- Route the Wires: Carefully route the wire to avoid sharp edges and heat sources. Secure the wire with clamps or ties to prevent movement during operation.

- Install the Control Switch: Mount the control switch in an accessible location. Follow manufacturer directions for wiring the switch to the winch.

- Make Final Connections: Connect the winch to the power source and control switch. Ensure all connections are tight and secure.

- Test the System: After installation, test the winch system to confirm all connections are safe. This step is crucial to ensure proper functionality and safety during operation.

Tip: Avoid common mistakes during the wiring process. Ensure wire ends are cut and stripped correctly, choose a reliable power source, and test the winch system after installation. These precautions help prevent issues down the line.

By following these steps, users can successfully wire their hitch mounted winch, ensuring it operates safely and effectively.

Installation of Control Switches

Types of Control Switches

When selecting control switches for a hitch mounted winch, users have several options. Each type offers unique features that cater to different needs. Below is a table summarizing various control switch options available for hitch mounted winches:

| Product Type | Link |

|---|---|

| Winch Control Switch for A2000 | Warn A2000 Control Switch |

| ZEON XD Winches | Shop ZEON XD Winches |

| VR EVO Winches | Shop VR EVO Winches |

| ZEON Winches | Shop ZEON Winches |

| ZEON Platinum Winches | Shop ZEON Platinum Winches |

| AXON Winches | Shop AXON Winches |

| VRX Winches | Shop VRX Winches |

| Classic and Specialty Winches | Shop Classic and Specialty Winches |

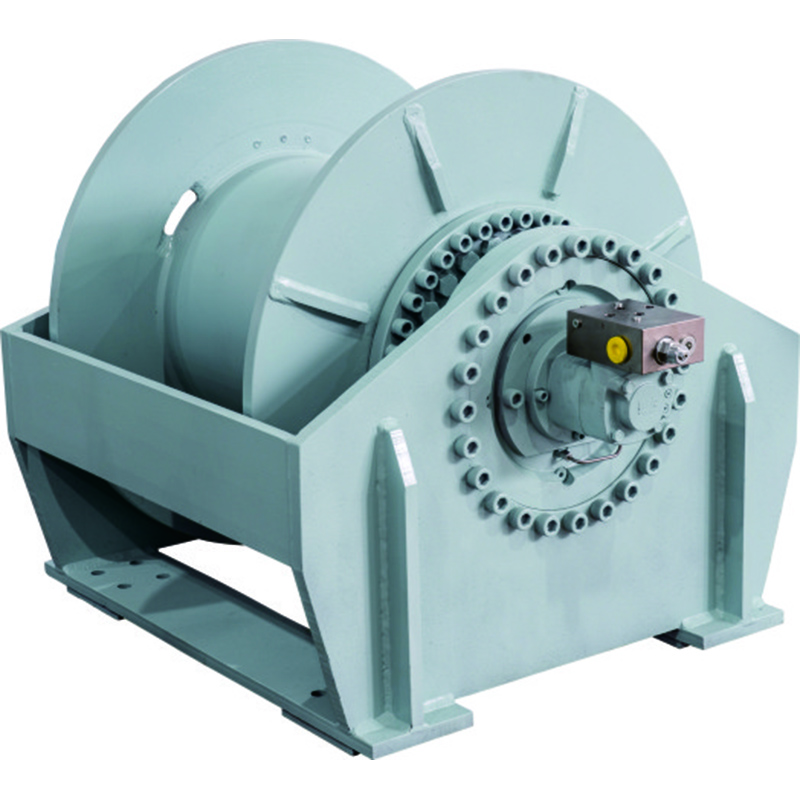

| Heavyweight Winches | Shop Heavyweight Winches |

| Industrial Hoists | Shop Industrial Hoists |

| DC Electric Hoists | Shop DC Electric Hoists |

| Hydraulic Hoists | Shop Hydraulic Hoists |

Mounting the Switch

Properly mounting the control switch enhances safety and functionality during winching operations. Here are some recommended practices for mounting control switches:

- Utilize multiple control options for safety and redundancy.

- Combine handlebar or dash switches with a corded remote for safety while winching.

- Consider using wireless controllers, but be aware of their limitations, such as lag time and dependency on battery and electronics.

By following these guidelines, users can ensure that their hitch mounted winch operates smoothly and safely, minimizing the risk of accidents during use.

Testing the Hitch Mounted Winch System

Initial Checks

Before testing a hitch mounted winch system, operators must perform several initial checks to ensure safety and functionality. These checks help identify potential issues that could lead to accidents or equipment failure. Key inspections include:

- Inspect winch cables for fraying.

- Check tie-downs for wear.

- Ensure decking bolts or screws are tight.

Conducting these checks allows users to address any concerns before engaging the winch. A thorough inspection can prevent costly repairs and enhance the overall performance of the winch system.

Functional Testing

After completing initial checks, operators should proceed with functional testing. This step verifies that the hitch mounted winch operates correctly under load. To conduct functional testing, follow these steps:

- Connect the Winch: Ensure the winch is securely connected to the power source.

- Test the Controls: Activate the winch using the control switch. Observe the response of the winch to ensure it engages smoothly.

- Load Testing: Attach a suitable load to the winch. Gradually apply tension while monitoring the winch’s performance. Listen for unusual noises and watch for any signs of strain.

- Safety Protocols: Maintain a safe distance from the winch during testing. Ensure that bystanders remain clear of the operational area.

By following these procedures, operators can confirm that their hitch mounted winch system is ready for use, ensuring both safety and efficiency during operations.

Troubleshooting Common Issues

Hitch mounted winches can encounter various issues that hinder their performance. Understanding common problems and their solutions can help users maintain their winches effectively.

Power Failures

Power failures are among the most frequent issues with hitch mounted winches. Users may experience several specific problems, including:

- Power supply issues: Battery drainage and insufficient power can hinder winch operation.

- Motor problems: Overheating and motors running without turning are frequent motor-related failures.

- Cable or rope malfunctions: Fraying, snapping, and cable slippage are common issues with winch cables or ropes.

- Remote control issues: Faulty wiring and weak signals can affect remote operation.

- Corrosion and rust: Oxidized connections and rusty components can impede functionality.

To resolve power failures, users should follow these troubleshooting steps:

- Check wiring connections for looseness or damage.

- Inspect the motor for any signs of wear or malfunction.

- Ensure proper installation and maintenance of the winch.

- For remote control issues, check the wiring and inspect for damage.

- If the motor runs but the drum does not turn, ensure the freespool is engaged.

Mechanical Issues

Mechanical issues can also affect the performance of a hitch mounted winch. Common problems include:

- Overheating: Allow the winch to cool down between uses and check duty cycle specifications.

- Line jamming or snapping: Ensure proper spooling and inspect the winch line regularly.

- Electrical issues: Check battery charge and connections, and clean corrosion on terminals.

- Freespooling difficulties: Lubricate the freespooling mechanism and keep it clean.

- Motor or gearbox issues: Inspect for wear and keep components clean and lubricated.

By addressing these common power and mechanical issues, users can enhance the reliability and longevity of their hitch mounted winches.

In summary, users can power a hitch winch through various methods, including batteries, jump start boxes, and direct vehicle power. Safety remains paramount; proper installation and maintenance are crucial to prevent accidents.

Tip: If unsure about installation or repairs, consider seeking professional assistance. This ensures compliance with safety standards and optimal performance.

For best practices, remember to inspect the winch regularly and maintain a safe distance during operation.

FAQ

What size battery is best for a hitch winch?

A 100 ah Group 27 deep cycle battery is recommended for optimal performance and runtime.

Can I use my vehicle’s battery to power the winch?

Yes, but it may drain the battery, preventing the vehicle from starting. Use caution.

How often should I inspect my hitch winch?

Inspect your hitch winch regularly, ideally before each use, to ensure safety and functionality.

Post time: Sep-26-2025