In the industrial field, winches, as important lifting and traction equipment, are widely used in engineering machinery, ship deck machinery, mining machinery and other scenarios. However, facing the wide variety of winch products on the market, how to choose a suitable winch has become a problem for many users. This article will provide you with a professional purchase guide from the aspects of winch type, performance parameters, and usage scenarios to help you find the most suitable one among many winch products. Understand the types of winches There are many types of winches. Different types of winches have differences in structure and function and are suitable for different operating scenarios.

Common types of winches are as follows:

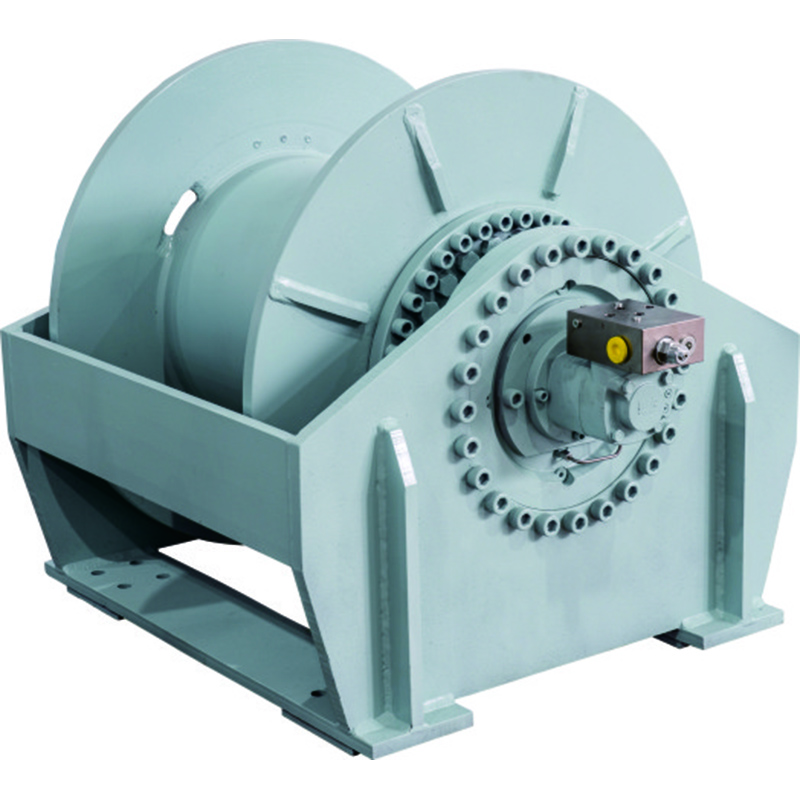

1. Hydraulic winch: It is composed of hydraulic motor, planetary reducer, valve group, etc. It adopts advanced modular manufacturing concept and mature processing technology. It has compact structure, high load-bearing capacity and operation reliability. It is widely used in lifting and traction mechanisms such as engineering machinery, ship deck machinery, construction machinery, and mining machinery. For example, the FJ series hydraulic winch has various models. Different models have different parameters such as the first layer tension, rope capacity, and wire rope diameter, and are suitable for different hydraulic motors and planetary reducers.

2. Electric winch: With motor as power source, it has the characteristics of easy operation and simple maintenance. It is suitable for some scenes with relatively stable power requirements. Like the FDJ series electric winch, there are different parameters such as tension, rope speed, drum bottom diameter, etc., which can be selected according to actual needs.

3. Hydraulic winch: It consists of a hydraulic motor, a planetary reducer, a winch head, an end cover, and a valve group with a two-way balancing valve. It has the characteristics of small size, light weight, high mechanical efficiency, large starting torque, good low-speed stability, and low noise. It is mainly used in various ship deck machinery. For example, the FJP series hydraulic winch, different models correspond to different load tension, anchor wheel diameter and other parameters.

Pay attention to performance parameters

When choosing a winch, performance parameters are the key considerations, which directly affect the working capacity and scope of application of the winch.

1. Pull: Pull refers to the maximum traction that the winch can exert, which determines the weight of the heavy object that the winch can lift or pull. Different operating scenarios have different requirements for pulling force. For example, in large-scale construction machinery, a winch with a larger pulling force may be required, while in some small operations, a winch with a smaller pulling force can meet the needs. Taking the FJ series hydraulic winch as an example, from FJ09-30 to FJ330-500, the pulling force ranges from 30KN to 500KN.

2. Rope capacity: Rope capacity refers to the length of wire rope that the winch drum can accommodate. It is related to the scope and depth of the operation. For example, in deep well operations or long-distance traction, a larger rope capacity is required. The rope capacity of the FJ series hydraulic winch varies from tens of meters to hundreds of meters depending on the model.

3. Wire rope diameter: The wire rope diameter affects the load-bearing capacity and safety of the winch. A larger wire rope diameter can usually withstand greater pulling force, but it will also increase the weight and cost of the winch. Users should choose the appropriate wire rope diameter according to the actual load.

4. Transmission ratio: The transmission ratio determines the relationship between the output speed and torque of the winch. A larger transmission ratio can obtain a larger torque, but a lower speed; a smaller transmission ratio has a higher speed and a smaller torque. Users need to choose a suitable transmission ratio according to the speed and torque requirements of the operation. For example, the transmission ratio of the FJP series hydraulic winch has different options such as 5, 5.5, and 16.

Consider the use scenario

Different use scenarios have different requirements for winches. When choosing a winch, you need to fully consider the environment, purpose and conditions of the operation.

1. Engineering machinery field: For example, in scenes such as construction and mining, winches are usually required to have a higher load-bearing capacity and reliability to cope with heavy operating loads. Hydraulic winches are widely used in this field because of their compact structure and strong load-bearing capacity.

2. Ship deck machinery: When ships are operating at sea, the environment is relatively special, and the corrosion resistance and stability of winches are required to be high. Hydraulic winches are small in size, light in weight, and have a large starting torque, which is suitable for the operation needs of ship decks.

3. Special environment operation: If the winch needs to work under special conditions such as corrosive media, overpressure, severe impact or ambient temperature beyond the normal range, the user must state these conditions when ordering so that the manufacturer can take necessary special designs and measures to ensure the reliability and safety of the winch. For example, in corrosive environments such as salt water, special treatment of the winch’s materials and structures is required.

If you have any questions in the process of choosing a winch, please consult our professional technicians. We will provide you with detailed technical support and purchase suggestions to help you operate smoothly.

contact:

email: sale1@flagup-hydraulic.com

tel: +86 18969419261

+86 18957499052

Address: No. 255, Fengcheng Road, Wangchun Industrial Park, Ningbo,China

Post time: Jun-11-2025